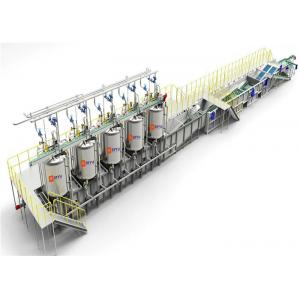

Continuous Sterilizing Retort Food Production Line Vertical For Canned Food

Scope of application:

vertical continuous sterilizing retort production line used for canned sardin and tuna fish

mainly applicable for products packaged with three-piece tin can, the continuous sterilization equipment boast high sterilization efficiency, effectively minimizing steam usage and environment pollution. Also, the vertical retort incorporates advanced integrated loading system without the need for manual loading, significantly lowering labor intensity, energy consumption and occupied space under the same output.

Sterilization technological process

1.The sterilizer will be injected a certain height of hot water before loading the cans in it. There are two purposes for the hot water injection, one of the reason for the sterilizer is the no basket structure, cans fall into the water from above mouth off sterilizer, buffer dropping can protect the cans. The other reason is for doesn't make the sterilization temperature reduce too much before the sterilization. The hot will be played the role of buffer when the cans fall into the sterilzer. Cans feeding while water overflowing.

2. When the sterilizer completely loaded the stipulated number of cans products, closed the tank lid, filled with hot water. The filled hot water can completely discharge the air out of the sterilizer.(If don't fill with water, it will need to use steam to blow the air in the upper sterilizer out of the tank).

3. When the hot water inside the sterilizer is discharged to empty, continue to heat up to the setting temperature to sterilizer.

4. It is supposed to do pressure maintaining and products cooling instantly after completed the sterilization. And then open the upper overflow pipe until the cooling ended. At last turn off all valves.

5. Opening the tank automatically, let the water inject into the tank as a buffer, because the tank door is doused into the water, it can make the tank from a vacuum state instantly. It can guarantee the cans to unload into the tank slowly.

Technical Parameters:

| Production speed of one retort |

600 cans per hour (5133 type can) |

| Dimensions (L*W*H) |

45.2m* 5.48m* 6.2m |

| Hot water kettle capacity |

17.5 m3 |

| Process kettle capacity |

117 m3 /unit |

| Sterilization kettle capacity |

8.6 m3 / unit |

| Power |

28kw |

| Steam pipeline |

DN80 per unit, 0.6-0.8Mpa steam pressure |

| Air compression/ pressure |

DN25 / 0.8Mpa |

| Cooling water pipeline/ pressure |

DN100 / 0.2Mpa |